Metal sorting with advanced sorting solutions

Today much attention is focused on new systems to upgrade the nonferrous product produced. The future of every operation depends on how well a system can effectively deal with constantly changing export markets, customer requirements and new mixes of materials available. The best processor is the one that can create furnace ready scrap that commands the best prices from the widest variety of customers.

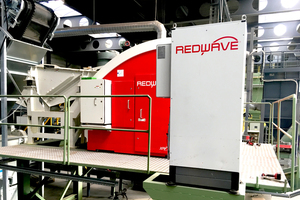

Today there are many options for getting a clean sorted product (see comparison table). But if you need a simple system with the flexibility for new sorting scenarios and capability to grow with new business all backed by the experience of the world leader in advanced nonferrous sorting, then the REDWAVE XRF/C is the only system designed for you.

Many equipment suppliers develop systems to fit a specific step in the recovery of high value materials from nonferrous mixes; depending on who you talk to they recommend some combination of induction, XRT, camera and XRF systems. But when a plant requires multiple sorting processes, the best solution is one that can do the most with the least and that is when REDWAVE comes into play.

13 years ago, REDWAVE invented the X-Ray Fluorescence (XRF) based sensor sorters for the recycling industry. At that time, the sorter was developed to effectively separate heat resistant glass and leaded glass in an input of mixed container glass. In collaboration with leading scrap recyclers, REDWAVE adapted the XRF system for the metal recycling industry to be able to do what no other sensor sorter could. With combination of XRF and camera technology in a compact industrial grade housing and using a free-fall concept rather than a conveyor belt, the sorted metal grades produced can reach purity levels high enough to sell directly to furnaces and refiners.

It´s an industry goal to cover the shredder’s operating costs by the revenue generated from the nonferrous output. But in a competitive market where every dollar counts, a fully sorted Zorba package can be worth up to 60 % more than the value of the Zorba alone. The REDWAVE XRF/C has a compact footprint of only 10 m2 allowing integration into almost any existing plant. Moreover, operating only with one machine and a single vibratory feeder, repair and maintenance needs are minimal in comparison to belt type machines or multiple machines.

Depending on the international market and other factors, the price of mixed nonferrous metals like Zorba, Zebra and Zurik can suffer a drop of over 50 % in value in a matter of months. The price of Zorba historically has experienced swings from the low 20’s up to near € 1 per pound. Sorted materials like aluminum twitch, die cast zinc and copper products tend to trade in tighter bands with their pricing linked to the prices of virgin metals on the LME markets. Sorting these materials with a REDWAVE XRF/C can greatly increase nonferrous revenues and allow a business to grow.

Global Sales Manager Martin Weiss says: “REDWAVE is proud to be the pioneer of advanced metal sorting using XRF. With more than 100 XRF-based sorting machines worldwide in operation we are the world market and technology leader for XRF-based sorting machines.” The REDWAVE worldwide customer base ranges from family-owned shredder yards to multinational corporations and each one has fulfilled their specific needs in nonferrous sorting with the REDWAVE XRF/C.