Large ripper handles up to 1000 kg of cardboard articles per hour

According to the Federal Environment Agency, 107 kg of packaging waste are produced per capita per year in Germany. A large proportion of this arises from cardboard elements of all sizes, which play an essential role in the safe transport of goods. But it is not only the end user who has to deal with packaging waste, but also the companies themselves – because the number of returns is rising steadily, so that in 2018 there was a total of around 280 million returns. To counteract this problem, sustainable and effective solutions must be found for the recycling of packaging.

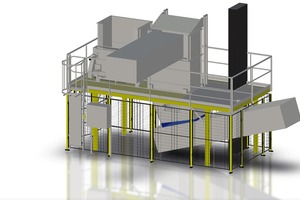

„In the logistics centres of companies with a high rate of goods dispatch, around 400 kg of cardboard boxes are torn up every hour“, explains Harald Erdwich, Managing Director of Erdwich Zerkleinerungs-Systeme GmbH. „However, due to seasonal reasons, for example during the Christmas season, much larger quantities arise, which must be shredded promptly in order to avoid a backlog in the processing of returns.“The cardboard ripper of type EKZ1400 from Erdwich, whose feed shaft has a power of 1.1 kW and whose ripper shaft has a drive power of 7.5 kW, can handle a maximum throughput of 1000 kg/h with continuous feeding, depending on the cardboard box material. Cardboard boxes with a maximum dimension of 1000 x 800 x 800 mm are shredded using an upstream conveyor system with 1000 mm nominal belt width and 2500 mm height of the discharge edge by means of a low-noise twin-shaft draw-in/ripper system.

Technical know-how for efficient cardboard shredding

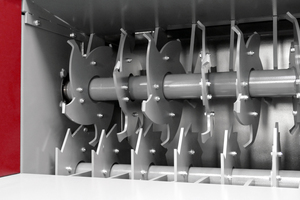

The EKZ1400 can be installed directly in the picking area or in the returns processing area in a fenced security area. The compact design is evidenced in the feed opening of approximately 1435 x 1200 mm and the installation height of approximately 965 mm. Both segments consist of a profile tube frame construction with bolted bearing shields. Furthermore, the plant has a draw-in and shredding rotor with two-part, bolted draw-in or ripper segments made of wear-resistant special steel and a large-dimension shaft bearing. In addition, there are electromechanical drives with compact gear motors and chain drives, which are mounted separately from each other for the draw-in and ripper shaft. Eight ripper elements and nine draw-in elements are installed. Both the shredding rotor with a speed of 57.5 rpm and the draw-in rotor with a speed of 6.5 rpm have a diameter of 520 mm. A flange frame at the top for the feed hopper and connection plates at the bottom for mounting the frame complete the EKZ1400.

The two shafts are driven independently: The slower feed shaft feeds the cardboard to the faster ripper shaft, which shreds the cardboard into the desired piece sizes. In this way, a high throughput can be achieved despite low drive power. Thanks to the tumbling rotation of the ripper shaft and the possibility of individually adapting the draw-in segments for the respective material, the shredding of the cardboard boxes can be carried out efficiently. Charging of this special version is carried out from above the discharge chute or conveyor. The shredded material is then transported to the baling presses by means of conveyor technology, or collected in containers for collection by a recycling company.

Easy maintenance and economical operation

Individually bolted and replaceable draw-in and ripper segments greatly simplify maintenance of the EKZ1400. The system also features low-maintenance chain drives. In addition, draw-in and ripper segments made of wear-resistant special steel ensure long service lives, resulting in low operating costs. The PLC control system with automatic reverse and cut-out control protects the machine against damage in the event of overload or resulting from massive parts that might accidentally get into the machine, thus ensuring safe and economical operation. „We offer the EKZ in various sizes and design variants, which we can also adapt to the respective application situation. It is also possible to convert the cardboard ripper for similar materials so that it can be used in other areas,“ explains Erdwich.

Lower costs through effective volume reduction

Shredded paper fibre can be reused around seven times before it eventually becomes unusable for paper and cardboard production. „Recycling is not only economically but also ecologically of the utmost importance, because the more waste paper is recycled, the less freshly cut wood has to be used for paper production,“ explains Erdwich. The cardboard shredder also contributes considerably to reducing transport costs by reducing the volume of the cardboard boxes. First the material is shredded for conveyor belt feeding, then it is compacted optimally for feeding to existing press containers or baling presses. The Erdwich plant can be precisely adapted to downstream conveying systems, but can also be supplied as a standard stand-alone machine.