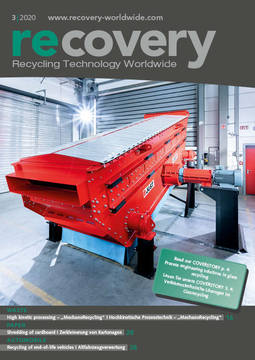

Doppstadt presents its highly efficient Inventhor Type 6

Doppstadt is consistently continuing its “Smart Solutions” concept with the Inventhor Type 6. The latest generation of slow speed shredders is designed to deliver maximum efficiency during shredding. At the same time, its intuitive operating concept and modular design guarantee maximum availability for a wide range of applications. As a result, it offers the best prerequisites to establish itself – just like its predecessor DW 3060 – as the first choice for anyone whose operations profit significantly from reliable and cost-optimized shredding.

High performance economically

implemented

The heart of the Inventhor Type 6 is Doppstadt’s unique VarioDirect Drive concept. It leverages Doppstadt’s patented gearbox. This combination of mechanical and hydraulic power continuously transfers the driving torque to the shredding system. By doing so, the speed of the shredding shaft can be flexibly adapted to the different material throughput, while the drive is very efficient delivering optimum performance at a constant speed. Thus, it is also possible to stop and start the shredding process even under load. And in case of blockage, the Vario gearbox can automatically switch to reverse mode in order to reliably protect the Inventhor Type 6 from any damage. The shredder is equipped as standard with a Stage-V diesel engine generating 260 kW.

Perfectly designed down to the

smallest detail

The range of possible applications of the Inventhor Type 6 is very diverse. From landfills and recycling plants through to waste wood processing facilities; from pre-shredding through to homogenization in thermal waste processing operations. Thanks to our multi tool concept, the shredder can be quickly adjusted to different materials by switching out the entire shredding system (shaft with teeth, toothed bar and, if necessary, limiters). At the time of market launch, this configurable shredding system is available with tooth sizes in L and M including limiters. Another feature of the Inventhor Type 6 ensures that the shredding process goes smoothly: The Smart Hopper. It has a feed hopper volume of 2 m³, which can be increased up to approx. 5 m³ by using auxiliary attachment panels. This Smart Hopper can either be loaded and tilted batchwise or it can be set at a suitable angle such that the material automatically slides into the shredding area. To further improve the availability of the Inventhor Type 6, many components have been optimized to ensure easy accessibility and quick conversions. Our easy access concept with counter comb opening Page 3 of 5 up to an angle of 90° makes the entire shredding area and engine compartment easy to access. This means that maintenance and switchover procedures can be carried out quickly and safely.

User friendly and easy to combine

The Inventhor Type 6 is available as standard with a semi-trailer and tracked chassis so that it can also be moved automatically when required by the operating conditions. In combination with other Smart Solutions from Doppstadt, it can be expanded into a high-performance complete solution, e.g. with the Selector 800 and its rugged SWS 800 spiral shaft screening deck. The Inventhor Type 6 can be operated for the most part automatically using its presettable material programs. In addition, the machine is equipped with a user-friendly terminal with plain text display and includes a remote control with display to allow the user to control it manually.

From landfills and recycling plants through to waste wood processing facilities; from pre-shredding through to homogenization in thermal waste processing operations. After intensive testing, the Inventhor Type 6 is about to be officially launched soon. Even though all of the major industry trade shows have been cancelled or postponed, the launch and subsequent sales will take place in May of 2020 as planned.