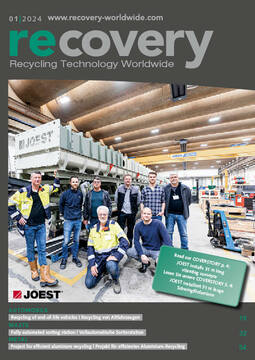

Coperion Recycling Innovation Center is up and running

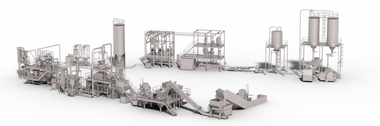

Coperion has successfully launched operation of its new Recycling Innovation Center. In this high-tech test center for plastics recycling applications, every recycling process step – from material handling and feeding to extrusion, compounding, pelletizing, material postprocessing and deodorization – can be tested. Extensively equipped recycling systems are available that can be modified in myriad ways, depending upon the specific requirements of the recyclate to be produced.

Coperion’s new Recycling Innovation Center is the perfect complement to the Herbold Meckesheim Test Center, where customers can simulate and test the mechanical pretreatment of plastic, allowing customers to experience first-hand the significant reduction in organic impurities by using Herbold Meckesheim’s hot washing system, as an example. Herbold Meckesheim has been part of Coperion’s Recycling Business Unit since 2022.

The ultramodern Coperion Recycling Innovation Center in Niederbiegen near Weingarten

The ultramodern Coperion Recycling Innovation Center in Niederbiegen near Weingarten

© Coperion

Recycling machinery on the cutting edge of technology

The Recycling Innovation Center is located in Niederbiegen near Weingarten/Germany, directly adjacent to Coperion’s existing Test Center for Bulk Solids Handling. Along with proprietary research and development projects, first tests have been performed for customers, in which new, sustainable products and recycling processes have been developed and tested. Coperion process engineers can modify the available recycling technologies such that the recompounds are manufactured with the highest efficiency possible while maintaining a consistently high level of product quality. The results achieved can then be effortlessly scaled up to production level thanks to the constant base parameters of all Coperion technologies.

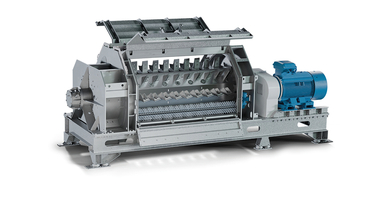

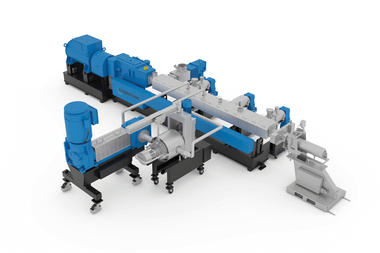

Coperion has equipped its new Recycling Innovation Center with the latest technology for every essential recycling process step – from material handling, feeding, extrusion, compounding and pelletizing to material postprocessing and deodorization

Coperion has equipped its new Recycling Innovation Center with the latest technology for every essential recycling process step – from material handling, feeding, extrusion, compounding and pelletizing to material postprocessing and deodorization

© Coperion

Every new technological development from Coperion that optimizes plastics recycling has been integrated into the Recycling Innovation Center’s machinery and can be tested there. For example, in the area of material conveying, the energy-efficient FLUIDLIFT ecodry® flash drying process is available – moisture remaining in recycling grinds following the washing process is reduced during material transportation. Moreover, the MIX-A-LOT bulk solid mixer, which can create premixes including flakes or powders, and the innovative buffer hopper solution using the ARW discharge agitator as well as the Smart Weigh Belt (SWB) feeder are integrated in the system. Coperion has also installed the ZS-B MEGAfeed side feeder, especially for extruding and compounding plastic recyclates with bulk densities starting as low as 20 kg/m³ at high throughputs. With its innovative design, the ZS-B MEGAfeed handles flakes and fibers such that they can be fed into a ZSK twin screw extruder in large quantities without energy-intensive compacting.

“The new Recycling Innovation Center shows how important it is for us to advance technology that helps our customers work towards more sustainability solutions and a functioning circular economy. The Recycling Innovation Center offers the ideal environment, both for our own research and development projects as well as for our customers, to master the challenges of plastics recycling”, said Frank Lechner, General Manager of Process Technology and Research & Development at Coperion.

“With this new Recycling Innovation Center, we’re in a position where we can simulate the entire plastics recycling process. Our customers can test the complete process, from mechanical pretreatment of plastics in Herbold Meckesheim’s Test Center up to compounding and pelletizing, prior to making the investment. As a supplier of entire recycling systems, we are very proud to be able to offer our customers this enormous added value”, said Massimo Serapioni, General Manager of Coperion’s Recycling Business Unit.