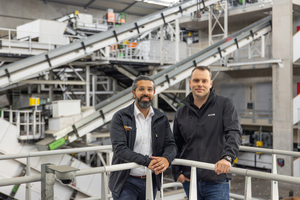

Bollegraaf and AGIR build Switzerland‘s largest PET sorting plant

The commissioning of a state-of-the-art PET sorting plant in Zurich marks the beginning of a new chapter in the Swiss plastics recycling industry. The plant, developed by AGIR in collaboration with the Bollegraaf Group, focuses on separating PET bottles into food and non-food fractions – a crucial step towards high-quality bottle-to-bottle recycling.

The plant was designed and built by Bollegraaf, one of the leading companies in recycling innovation, and features advanced automation and state-of-the-art sorting technology. The Bollegraaf Group supplied all plant components except for the NIR separators and the bag opener, including a state-of-the-art ballistic sorting machine (Elliptical) and conveyor belts. The AWS 330 StarScreen (screen) is also part of this plant and is a new machine for a PET plant. Although it was originally designed for 40 t per shift, it has already reached peaks of up to 70 t, with the potential for further scaling.

“Thanks to Bollegraaf‘s efficient layout and engineering, we are exceeding expectations – and we still have capacity for growth,” says Benedikt Bader, Operations Manager and Head of PET Recycling at AGIR AG. “Our goal is to maintain a closed loop in Switzerland that ensures that every bottle returns to the market as a new recycled PET product.”

The plant supports PET Recycling Switzerland, which centrally manages bottle collection in Switzerland. The country does not have a deposit system, but the Swiss PET recycling rate is 83 %. The bottles are returned voluntarily by consumers via supermarkets and local collection points and then delivered to AGIR for processing. The plant is also future-proof and adaptable to new market conditions. As the trend is moving away from HDPE to PET for milk bottles, the plant is designed to adapt to new material types with minimal modifications.

Bollegraaf‘s solution stood out thanks to its optimized logistics, space-saving layout, and reduced use of conveyor belts – all of which contributed to more sustainable and cost-effective operations.

Given the growing demand for PET recycling throughout the region, this project positions AGIR as a key player in Switzerland‘s circular economy.