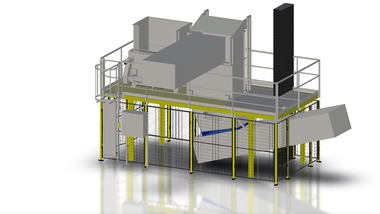

Bergmann: Roto Compactor to take off

With the installation of a new Siemens PLC control, LAN (Local Area Network) connection will be possible by default as of this model year. Thus, the standard program enables users to monitor their machines without problems, to query parameters and to flexibly change them according to their wishes. In future, new programs designed according to special customer demands can be conveniently sent by e-mail and loaded up via SD card.

The extremely user-friendly menu facilitates handling. Moreover, the standard languages German/English are designed for worldwide use. The additional module even provides the option for WLAN connection. Further new functions also support the ease of use and the optimization in the operating process. Whether it is the 7-fold keyboard with reset button, the encapsulated push button of protection class IP 65 with moisture resistance or the laterally mounted water nozzles (full cone nozzles) which provide better containment of the dusts arising in the crushing process as a result of an improved location and an extended spray field - the more powerful water pump (230 V) plays a decisive role. Furthermore, a quietly running pump for hydraulics (lifting of the compaction unit) is used as a standard, reducing the noise level considerably. Also, much has happened in steel construction and mechanics.

In model PS 1400-E, type 189, conically arranged, smooth inside walls ensure easier removal of the filled waste sacks. The locking of the sacks on the walls is facilitated by surface-embedded grooves for the sack holder. A smaller, compact motor bonnet arranged above the compacting element enables the easy passage of the filling material, in particular when loading from the top. Developers and engineers paid particular attention to the access to the packaging station. Thus, opening the access element to reach the engine room/hydraulics is now considerably facilitated by a 2-part hinged door. Installed safety end-switches interrupt the machine run. The removal door for the compacted bales have also been equipped with a one-hand locking system which is easier to use.

As a result of this great number of improvements, the Roto Compactor PS 1400-E, Type 189 from Bergmann makes operation even easier and more comfortable, with the easy-to-handle control for many functions contributing considerably to this.

Hall A5, Stand 300