AMANDUS KAHL presents solutions for pelletizing additives and plastic waste

At K 2025, AMANDUS KAHL will be presenting innovative technologies for sustainable plastics processing. The focus will be on dust-free pelletizing of additives and the processing of plastic waste for chemical recycling. At K 2025, the specialist for process and plant engineering will present its proven flat die pelletizers – and show how powdery materials and temperature-sensitive plastic fractions, which are produced after production or after end use, can be converted into dimensionally stable pellets in an energy-efficient and gentle manner.

This year, the world‘s largest trade fair for the plastics and rubber industry, with over 3000 exhibitors from almost 60 countries, will focus on sustainable recycling management, resource conservation, and the responsible use of plastics. In this context, AMANDUS KAHL will demonstrate how additive mixtures can be produced economically and reliably using robust and low-maintenance machines. In addition, the company will present solutions for the efficient processing of recyclable materials, for example for chemical plastics recycling.

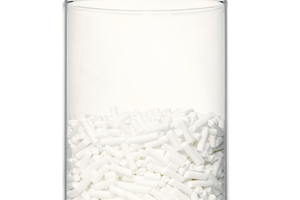

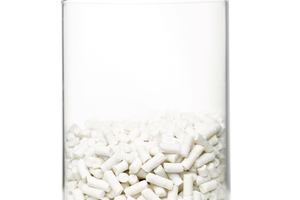

Dust-free dosing of polymer additives

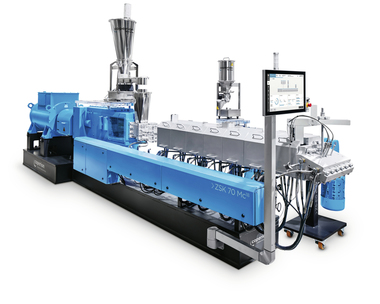

Among other things, AMANDUS KAHL will demonstrate its systems for dust-free pelletizing of additives. Powdered additives are considered difficult to dose, tend to segregate, generate dust that can be explosive at fine particle sizes and in certain concentrations, and pose challenges for transport and storage. To minimize the risk of explosion, powdered additive mixtures are compacted. This reduces dust formation and increases safety in the production process. With its flat die presses, AMANDUS KAHL offers a solution for press agglomeration that can also be used for temperature-sensitive additives: The powders are converted into low-dust, compact pellets – so-called No Dust Blends. These are characterized by good dosability, reduced segregation, and a stable structure. For several decades, the 33 and 38 series in particular have proven themselves here, including the 33-390 and 38-600 presses, which are successfully used in numerous applications worldwide – especially for the pelletization of stabilizers.

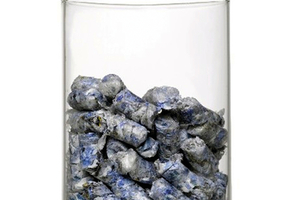

Recycling plastic waste

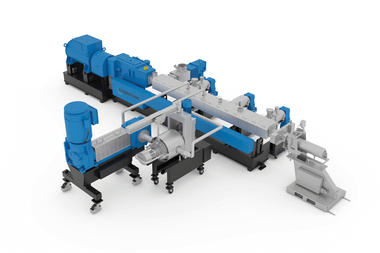

AMANDUS KAHL will also be focusing on the recycling of plastics at K 2025. Instead of recovering energy from plastics, material recycling aims to recover the polymer building blocks. This is where larger pellet presses such as the 39-1000 and 45-1250 come into play: They prepare even large-volume, inhomogeneous, and temperature-sensitive plastic waste for further recycling by significantly increasing the bulk density and ensuring a stable pellet shape. This facilitates handling and, in particular, efficient further processing in the extruder, while also reducing transport and storage costs. In addition, the KAHL belt dryer ensures stable process conditions by reducing moisture in the material and homogenizing it before it is pelletized. The result: a stable, reliable process with high product quality.

At the AMANDUS KAHL booth, visitors can gain insight into the various machine designs for the plastics and chemical industries – also available in stainless steel or adapted to GMP and ATEX requirements on request.

Hall 10, Stand B51