Advanced C&D processing line operational at Zanker Recycling in California

23.08.2019

Zanker Recycling in San Jose, California/US

Zanker Recycling in San Jose, California/US

Source: Zenrobotics

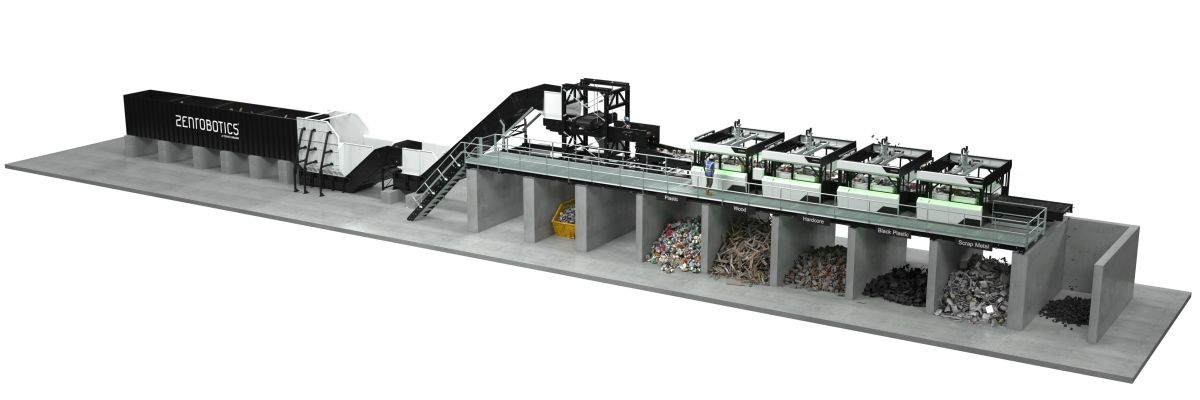

A new advanced waste sorting facility, equipped with four ZenRobotics Heavy Picker robot arms, is now operational at Zanker Recycling in San Jose, California/US. Zanker is a leader in advanced recycling in the Bay Area. With the new robotic processing line, Zanker Recycling will increase both waste recovery rates and overall processing capacity.

“The advantage of deploying AI robotics to recycling differentiates Zanker from our competitors,” says Michael Gross, Director of Sustainability at Zanker Recycling. “Reaching our diversion goals is extremely important to us,” he concludes. To reach its diversion goals, Zanker chose ZenRobotics’ US dealer Plexus Recycling Technologies as their partner in realizing an advanced waste processing facility that incorporates ZenRobotics’ AI-powered waste sorting robots for improved sorting efficiency.

Material feeding is highly automated throughout the process in order to maximize efficiency. The front end operates 50 % of the time to process the inbound material during the opening hours. In the middle of the process there are two large dosing bunkers that can store up to 100 tons of material. ZenRobotics’ AI software, ZenBrain, controls these along with all equipment downstream to allow a very smooth-running operation focused on maximum recovery and efficiency.

Students from the nearby Boys & Girls Club of Silicon Valley, located in Alviso, participated in the naming of Zanker's four new AI-powered robots. The winning naming entries were Clean-up Carl, Magneto, Snatcher and Thrasher. The robots operate 20 hours per day with total system production of 150 000 t/a, increasing diversion of recyclables by 20 %. The ZenRobotics Heavy Pickers will do the heavy lifting on the bulky material sort line. Each of the four arms will be picking 2000 picks/hour, sorting objects weighing up to 30 kg (60 lbs).

“We’re excited to see ZenRobotics Heavy Pickers at work in this advanced materials processing facility. The growth potential on the US market is substantial. Robots are ideal for long operating hours and designed to increase process efficiency,” says Rainer Rehn from ZenRobotics.