WEEE recycling and its problem

Black plastic parts occur increasingly often in daily life and have therefore become a large challenge for recycling and separation technologies. In its headquarters location in the town of Penzberg in the Federal German state of Bavaria, hamos has been producing already for many years, as one of the worldwide leading suppliers of electrostatic separation technologies, complete recycling lines, with which it is possible to separate black plastics with great success into clean separate fractions according to the types of materials involved. While the separation technology used by hamos works irrespective of the colour, other separating technologies such as e.g. optical sorting systems are by comparison still very much in their infancy.

Aside from the “metals” resource, the “plastics” resource should also have to play a large role in recycling. This is however mostly not the case in practice, as recovery of clean plastic fractions from electrical & electronic waste is much more laborious than recycling of the metals. The cause of this is that presently available sorting possibilities can only exploit the entire plastics raw material potential to a limited extent. A large proportion of this material is therefore lost and is then used, for example, to recover thermal energy. The following article is concerned with various possibilities, such as how efficiency of plastics recovery can be raised and how a higher proportion of plastics in electronics waste can be made into valuable, clean plastic fractions.

The granulate material purities achievable with electrostatic separation are very high and sometimes stretch beyond 99.5 %. This means the recyclate is so clean that it can easily be used again to produce high-grade compounds and these in turn can be processed into new technical products. In this way, particularly valuable technical raw materials can be recovered from materials that cannot be processed further as such. Depending on the application, expensive virgin material can be entirely or at least partially replaced by more favourably priced recyclate. Many products can then be produced entirely from recycled plastics. This is an important economic aspect, especially against a background of rising oil and raw material prices, and it also makes an important contribution towards environmental protection through avoidance of waste.

Plastics from electronic waste

By definition, “electrical and electronics scrap” arises from a number of different types of equipment. As mainly no material pre-separation into clear-cut pre-separation according to types of materials is made in recycling companies while processing e.g. small domestic appliances, this mixture of materials ends up in shredding plants. This leads to mixed plastics waste remaining after the metal fraction has been separated out, a material that consists not only of different plastics, but that is furthermore contaminated by dust, wood, pieces off glass, residual metals, elastomers and many other undesired contaminants.

The task of plastics recyclers then consists of production from this complex mixture, corresponding to Fig. 1, of re-usable plastics fractions. As experience shows, particularly high demands are placed on purity of the recyclate, as these often compete with virgin materials. On the other hand, there is also a task here of recovering the highest possible proportion of clean plastics, so that as little as possible good material is lost. Plastics recycling is only economic if highest possible material fractions proportions are recovered.

It must be absolutely observed in recycling however that not all plastics can be brought back into circulation, on account of legal requirements. Among these, it is particularly plastics containing brominated flame retardants that may not be re-used and that therefore have to be separated off into their own separate fraction. There are furthermore also many other plastics present, such as e.g. PC or PMMA, which are only present in low amounts of 1 – 2 % in the entire plastics fraction. On account of the low amounts of these plastics, recycling only pays off to a limited extent, as the effort required to recover these plastics is sometimes higher than the possible return from them. The largest proportion of plastics in mixed electronics waste consists of PS and ABS, as well as PP. A plastics processing company’s experience has shown these materials make up around 55 % of the input material and that 40 to 50 % of the input material consists of uneconomically recoverable plastic, flame retarded materials and impurities. Work is however ongoing to minimise this fraction with new processes and thereby to raise the return.

It is not only the type of plastic that plays a large role in plastics recycling, but also the colour. Plastics in electronics scrap involves a particularly high proportion of black plastics, which can amount to between 60 and 75 % (in toner cartridges, it sometimes amounts to more than 90 %). The reason for this is that not only the fact that black is “modern”, but there is also a role played by cost aspects. While for example colouring a plastic red makes it up to 30 % more expensive, the extra costs for a black coloured plastic are minimal.

Plastics sorting

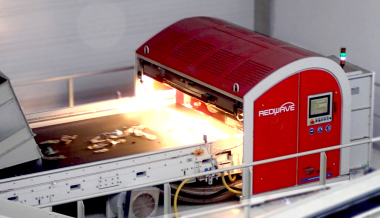

In sorting post-consumer packaging waste from the “yellow bags or bins” used in Germany to collect such waste, opto-electronic sorting equipment has become widely adopted, which is able through use of near infrared recognition (NIR) to automatically recognise e.g. plastic bottles in PET, PE, PP and other materials, and to clearly identify the plastics by their individual categories. It is then possible with the NIR technique by using downstream air-blast units to sort not only complete bottles, but also flakes and other granulated recyclate materials.

It has of course been attempted to also use NIR sorting in the area of plastics from electronics scrap. There was here however for a long time the large disadvantage that only light colour plastics could be recognised, while dark plastics could not be recognised. When considering that only around 20 to 40 % of plastics in electronic scrap has light colour, on the other hand that good material totals only around 55 % of the entire amount used, it was established that this NIR technique was not economic for sorting plastics from electrical & electronics scrap according to the EU’s WEEE waste electrical & electronic equipment directive. A large proportion of recyclable ABS and PS was not recognised, so ended up as non-recyclable waste. Despite further development of NIR sorting, experts still view its economic use with scepticism.

If it is wanted to exploit the valuable “plastics” resource to its fullest potential, it is therefore absolutely essential to also recover the proportion of black plastics in as high as possible purity according to the type of plastic. Electrostatic separation technology can be used with great success for separation of such mixed plastics from electronics scrap.

Completion of the separation process results in receipt of ABS or PS fractions with high purity of in some instances more than 99 %. Electrostatic separation takes place irrespective of the colour. Completely black coloured material mixtures can therefore also be easily separated.

But electrostatic separation has a catch: Complex mixtures, as arise in electronics scrap cannot be simply processed as such. There has to be a form of pre-concentration applied prior to the electrostatic process, so that undesired plastics such as those containing for example flame retardants, can be separated. A combination of dry and wet processing technologies is recommended for the required plastics pre‑concentration from these complex material mixtures.

Dry and wet separation processes

It is possible with dry separation processes to separate all undesired foreign materials such as for example film, dust, fibres, etc from course pre-shredded WEEE plastics materials, e.g. those in the particle size area of < 50 mm. A combination of air classifiers, settling tables, or other processes are used for this purpose.

It is furthermore recommended to sieve the fine fraction as much as possible and to remove metal parts that may possibly still be present. The material is then ideally prepared for the following process stage, wet separation.

A number of float-or-sink basins containing fluids of different densities, following one after the other, are used in the wet separation process. With a density of approx. 1.08 kg/dm³ used in the first stage, all product groups (PS, ABS, PP etc) float, due to their lower density, while undesired foreign materials, including flame retarded plastics sink, and can be disposed of.

A subsequent further separation stage with water (density 1.0 kg/dm³) not only rinses away the residual separation fluid from the first separation stage, but also enables separation of PP and PE as the floating fraction and PS and ABS as the sinking fraction. It is in this way that sought-after concentrated PS and ABS and concentrated PP and PE fractions can be produced from WEEE plastics.

Undesired foreign materials

But these PS and ABS mixtures are still significantly contaminated by high amounts of foreign materials. Above all here, wood, which originates for example from shredded loudspeakers, radio housings, palettes etc. Corona-roll type electrostatic separators have proven themselves in separation of wood fractions. Different electrical conductivity between moist wood and dry plastic is used here for separation. The plastic is practically free of wood after this separation stage. Conductive rubber is also simultaneously separated in this separation stage.

Separation of PP

The “sought-after plastics ABS and PS” lie in a density range of approx. 1.05 kg/dm³. But it has been shown in recycling plastics from electronic scrap however that mineral filled polypropylene (so‑called PP20) also lies around this density area, as a material that has been filled for cost reasons with 20 % talc. Presence of PP together with PS or ABS is however undesired, as the quality of granulate or compounds suffers considerably from the PP content.

Separation process of ABS and PS

It is easy to separate ABS and PS from each other with the electrostatic separation technology. A double-stage separation process is used for this purpose.

In the first separation stage, a pure ABS fraction is firstly separated from an ABS-PP mixture that has been pre-concentrated by float-or-sink separation and then dried. This is achieved by selectively charging the materials in the plastics mixture in a special charging unit. ABS takes on a positive charge, the other plastics PS and PP a negative charge. The ABS is then separated from the product stream with a positively charged electrode as a clean fraction with purity in some cases of > 99,5 %.

The remaining fraction, consisting mainly of PS and some residual ABS and PP, is taken up in a second separation stage, in which it is also electrostatically charged. The PS is separated by the electrode system as a clean PS fraction of purity > 98.5 %. A so-called mixed fraction is also obtained, consisting of PS and ABS, which is mixed in with input material. Filled PP is obtained as a further fraction, mixed with some PS. The PS and ABS fractions are largely free of PP after electrostatic separation – ideal prerequisites for production of clean high-grade compounds.

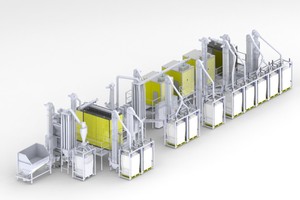

A separation line for plastics from electronics waste therefore consists of two hamos EKS separators working on electrostatic principles in the first stage. These two pieces of equipment work parallel to each other, separating together at a rate of approx. 1500 kg/h. As the ABS proportion separated in the first stage accounts for approximately 50 % of input material, only approx. 750 kg/h comes out of the second stage with its single hamos EKS separator. So approx 1500 kg PS and ABS per hour can be separated with use of the hamos KRS line equipped with three electrostatic separators, whereby the PP20 fraction is separated off in its own separation process. Fig. 2 shows a KRS installation.

All of the machines are of course linked together by bucket elevators, conveying screws, etc. Equipment for filling of separated fractions into large “Big Bags” is also equally standard, so that the entire hamos KRS separation line can work in 24-hours operation, seven days a week.

Separation of elastomers

Elastomers present a large problem in recycling of mixed plastics from electronic scrap. These elastomers arise in the form of rubber, silicone, elastomer foams, etc. They have the unpleasant property of not melting during extrusion of granulated material, leading to reduction in quality of the finished product, despite accounting for only a small proportion of the material. These elastomers therefore absolutely have to be removed from the granulated material.

ABS and PS mixtures charge mainly negatively in electrostatic separation. So they are mainly separated along with the equally negatively charged PS fraction. The ABS fraction is practically free of rubber after electrostatic separation!

The hamos RSS rubber separator has been developed by hamos in order to also free the PS fraction from rubber. The undesired elastomers can be almost entirely removed from highly concentrated waste fractions with this equipment. The energy consumption required here for separation is minimal. Fig. 3 shows such an elastomer fraction.

Recycling of toner cartridges

Recycling of toner cartridges is a particular challenge. Approx. 370 000 000 toner cartridges were sold worldwide in 2010, whereby certainly most of them had been used and emptied from printing tasks already within a short period of time, thereby soon becoming scrap items. Specialised refilling companies refill some of these toner cartridges, others are collected by the producer and recycled. But the largest proportion of them end up as refuse, as there has been no suitable recycling process in place for this type of mixed product (Fig. 4).

But electrostatic separation is also ideal for recycling plastics from toner cartridges. Following shredding, removal of residual toner ink, separation of metal parts and float-or-sink separation to concentrate the plastic materials, a completely black mixture of PS and ABS is obtained. This material has particle size < 10 mm and is then largely separated from metals and elastomers in a first stage by the hamos KWS corona-roll electrostatic separator. Elastomers in toner cassettes are mainly electrically conductive, so they can be easily separated out by conductive/non-conductive material separation. As trials have shown, it is possible with multi-stage separation to reach rubber contents as low as just several ppm!

Subsequent separation in the hamos EKS electrostatic separator easily separates out clean plastic fractions such as ABS or PS. As separation takes place irrespective of colour, these completely black materials can be easily separated into fractions of very high purity.

After running through the recycling line, the granulated ABS and PS materials become so clean that they can be used again in production of new toner cassettes. So a completely closed circuit is obtained, “from the toner cassette to waste, via clean granulate to the new cassette”.

A large part of the valuable resources contained in a toner cassette are recovered in this way. It is therefore possible to utilise almost the entire recyclable material potential in these toner cassettes. This was not possible in the past, as no success had been achieved in separation of the black plastics from each other into separate pure fractions according to the type of plastic. Without electrostatic separation possibilities, most of the black plastics involved would have been thermally recovered, i.e. they would have landed up in incineration.