Thinking battery recycling holistically

According to the German government‘s plans, up to 10 million electric vehicles and 500 000 electric commercial vehicles are to be sold in Germany by 2030. A third of buses in local public transport are also to be equipped with electric drives within this period. On average, four battery modules are installed in every electrically powered truck and as many as eight in every electric bus. This will drastically increase the demand for raw materials for core components of battery technology such as lithium, cobalt and nickel.

To meet the increased demand for raw materials, it is necessary to promote the recovery of spent batteries and successively increase the recovery rates. An important step here is to gear product design to recyclability at the end of the service life.

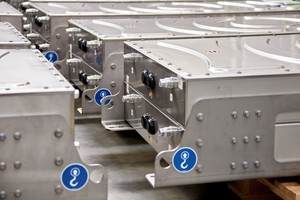

With the project “Bætter Recycle – Battery Recycling and Dismantling for E-Mobility and Optimization through Recyclable Design”, funded by the Hessen Agentur, the research partners Akasol AG and the Fraunhofer Research Institution for Materials Recycling and Resource Strategies IWKS want to develop an automated recycling process for the efficient dismantling of traction batteries and the recovery of raw materials. This also includes optimizing the battery design with regard to recyclability.

The aim of the Bætter Recycle project is to implement a process that verifies the condition of battery systems and, on the basis of the relevant parameters, decides whether they can be used in a second-life application or sent directly to recycling. In this context, the entire product life cycle of lithium-ion batteries – from design to recyclability – will be analyzed and evaluated in two steps.

In the first step, recyclability will be considered at the design level. Problematic disassembly steps will be uncovered, which could subsequently be optimized in the design of future battery systems. In the further course, the materials used will also be tested for their recyclability in order to avoid poorly recyclable materials in future developments.

Another aspect that is being considered within the funding project is the actual reusability of the various modules for practical use in second-life applications. Specifically, it is being examined to what extent the recovered modules from the battery systems can be converted into stationary battery storage units with the aid of a modular system. This will extend the service life and increase the economic efficiency of the modules. Parallel to the development of the dismantling and recycling process, the new processes will be evaluated according to various parameters such as environmental impact, material criticality or costs in order to evaluate the sustainability of the overall process and to identify influencing factors.

The project described is intended to improve the ecological balance of lithium-ion batteries and thus reduce CO2 emissions. The findings from the project are to be applied as transferable balancing concepts for product cycles of all kinds – regardless of the size, design or application of a battery system.