Profitably closing the plastics cycle

A majority of the plastic that exists will be used just once and will not be recycled. In Europe, only about 30 % of the plastic produced in 2017 went on to be recycled. Enormous amounts of plastic waste are disposed of in landfills or incinerators, practices that pose risks to air quality, wildlife, public health, and the food chain. On top of that, the oceans are suffering from a flood of plastics: of the estimated 150 mio. t of trash floating in the world’s oceans, roughly a third of it is plastic.

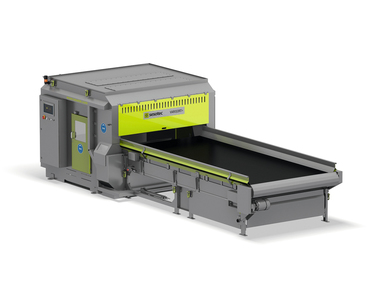

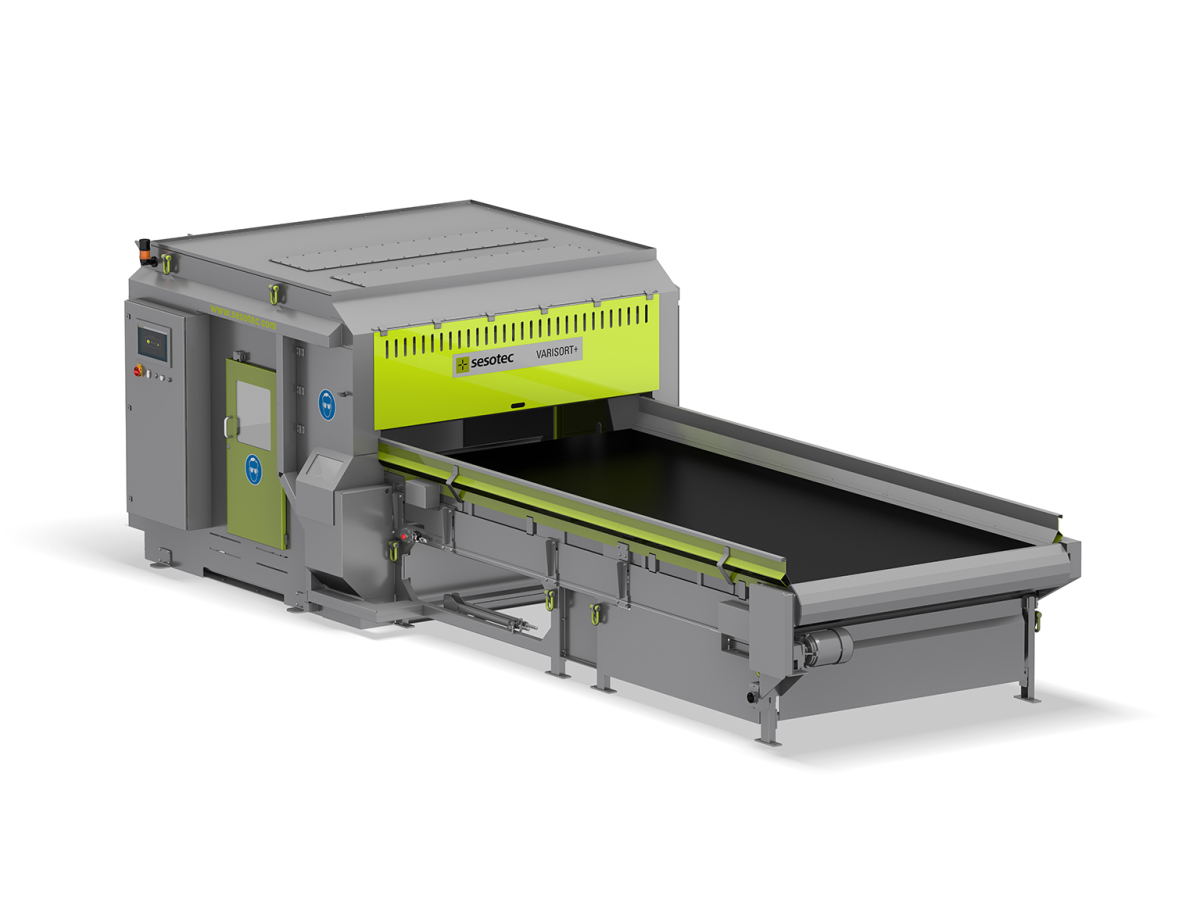

VARISORT+ detects and separates plastic types, colors, and shapes, as well as metals and foreign objects, with the utmost accuracy and reliability in order to provide the best possible sorting results, even with poor-quality materials

VARISORT+ detects and separates plastic types, colors, and shapes, as well as metals and foreign objects, with the utmost accuracy and reliability in order to provide the best possible sorting results, even with poor-quality materials

© Sesotec GmbH

In order to counteract this development and convert plastic waste into useable raw materials, the EU introduced legislation in October 2018 that requires all plastic packaging to be either reusable or easily recyclable by 2030. As industry has begun to make adjustments to meet this 2030 deadline, the purity of recycled plastics has become a central issue. Recycling plant operators are having to implement preparation processes that can bring the purity of their recycled plastics up to a level suitable for reuse in food packaging and other sensitive applications. The goal is to produce recycled plastic granulate with the same quality as virgin plastics by sorting out the impurities.

Inconsistency in the availability of raw materials can lead to inconsistent quality in plastic packaging. Sorting through materials of highly variable quality poses a tremendous challenge for plastic recycling plants, as poor quality granulate can have many negative consequences: from reduced material throughput, to a higher loss of good material, to lower degrees of purity in the sorted material fractions, to more frequent downtime for cleaning and maintenance. Each of these factors detracts from the efficiency, and thus from the profitability, of sorting and recycling processes.

Sorting multiple material streams with the new VARISORT+ sorting system

Sesotec has developed a new sorting system for recycling plastic bottles and trays: VARISORT+. The efficiency of this new sorting machine is what sets it apart. Even when working at an incredibly high material throughput rate of up to 8 t/h, VARISORT+ detects and separates plastic types, colors, and shapes, as well as metals and foreign objects, with the utmost accuracy and reliability. The newly redesigned VARISORT+ has been optimized for reliable system availability, quick cleaning, and easy maintenance. A removal accuracy of up to 99 % ensures that sorting fractions achieve the highest degrees of purity.

Another advantage of the VARISORT+ system is its flexibility, allowing for the combination of up to three sensors (N = near infrared, C = color/shape, M = metal). The sorting system can also be equipped with innovative new FLASH technology for optimal color detection, which can even detect bottles made with additives. Sensor upgrades are available at any time and the optional three-chute-design enables simultaneous sorting into three material fractions.

VARISORT+ sorting systems are designed to accommodate conveyor belts supplied either by the equipment manufacturer or the customer (working widths of 1024 mm, 1536 mm, 1920 mm, or 2816 mm).

Profits climb due to the flexible system configuration of VARISORT+, which can be adjusted according to the quality of the input material or degree of contamination. Excellent sorting results with up to 99 % purity can be achieved even with poor-quality input materials. The low maintenance and cleaning requirements for VARISORT+ also play a key role in increasing the system’s overall efficiency.

“Plastic waste can no longer be treated as rubbish, but as a valuable resource,” says Michael Perl, Group Director Sorting Recycling at Sesotec. “The solution is a circular economy. This means we need more and higher quality recycling. Sesotec supplies high-performance sorting equipment for this purpose, including the VARISORT+.”