Improving the recovery of recyclables from WEEE at primary treatment facilities

The scarcity of resources and the concept of sustainability are central issues for the economic and social development of industrial nations. Germany possesses extensive reserves of raw materials in the construction materials sector. Their extraction, however, is often associated with the destruction of conservation-worthy natural environments. With regard to those raw materials needed for high-tech applications, on the other hand, Germany is dependent on imports.

Research environment

The project entitled “Innovation-based increase in the recovery of recyclables” (InnoWert) has been undertaken by Nordhausen University of Applied Sciences with the help of the Institut für Angewandte Bauforschung Weimar gGmbH (Weimar Institute of Applied Construction Research – a non-profit organization, IAB) and is supported by the Free State of Thuringia with funds from the European Social Fund (ESF). It addresses two key areas of work with the topics of waste electrical and electronic equipment and building materials. Focus of the findings described in the following is the optimized recycling of waste electrical and electronic equipment (WEEE) at primary treatment facilities.

The project is conducted as one of two start-up projects in the newly established Thüringer Innovationszentrum für Wertstoffe (Thuringian Innovation Centre for Recyclables – ThIWert) in Nordhausen. This is a cooperative institute of Nordhausen University of Applied Sciences, Bauhaus University of Weimar (b.is) and the Institut für Angewandte Bauforschung Weimar gGmbH (IAB). The development of the Institute is supported by the Free State of Thuringia and is co-financed with resources from the European Regional Development Fund (ERDF).

The ThIWert sees itself as a partner for industry and business in the state of Thuringia, but also for regionally and nationwide-based research institutes, universities and colleges. Together with its partners, it works on solving waste management and disposal problems, the development of new technologies and the creation of waste management and disposal concepts to create added value for the environment, the people as well as the regional and nationwide companies.

Goal of the ThIWert is to develop, test and optimize processes and products from recycling technology as well as complex recycling plants and their plant components in modular design.

Problems in the processing of waste electrical and electronic equipment at optioned primary treatment facilities

WEEE consists essentially of metal-plastic composites. To make these accessible with regard to the recovery of metals and critical resources of strategic economic importance, they must be broken down at reasonable cost and any recyclables and hazardous materials contained removed. The further processing of WEEE at primary treatment facilities can increase revenues with the sale of separated materials and contribute to the safeguarding and creation of jobs at optioned primary treatment facilities. At the same time, the inclusion of people with a handicap, like, for example, at the project cooperation partner, the Nordthüringer Werkstätten (NTW) in Nordhausen, can be maintained.

At small-scale primary treatment facilities, mainly conventional tools and the manual skills of the employees are utilized. This type of manual disassembly of WEEE is only worth it for equipment with a high potential of recyclables. For equipment that is adhesively bonded, pressed or put together with special screws, dismantling is much more time-consuming. At the same time, on account of the plastics used in small domestic appliances, additional disposal effort is required as there are hardly any buyers for unsorted plastics on the recycling market. For this reason, plastic fractions have to be disposed of at cost by the primary treatment facility, which in turn leads to additional costs and makes further manual processing of appliances in Collection Group 5 unprofitable at the present time.

As part of the project, the application of different mechanical processing and separating techniques for plastics, metals and other recyclable fractions from WEEE is to be tested and recommendations for further action derived from the findings. The production of saleable waste-derived resources is intended to help small-scale primary treatment facilities remain economically viable and safeguard jobs. On the basis of the findings obtained, a concept for energy-efficient and modular processing is being developed for possible integration at optioned primary treatment facilities. The plant concept is to be configured such that it is possible to respond quickly to market fluctuations and output material can be adapted to meet the requirements of the further processing facilities.

Composition of small household appliances

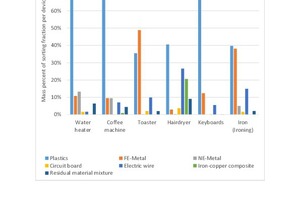

To find out about the recyclables content and the separability of WEEE in Collection Group 5, manual disassembly tests were conducted. In the selection of the devices, typical representatives of small household appliance group were chosen as these have already been identified as the main group in previous studies on the return of WEEE in the public space. On account of the high plastic content, here there were already problems with their economically viable sale to treatment plants. The group of small household appliances comprises domestic appliances in daily use such as kettles, coffee machines, toasters, hairdryers and irons. For comparison of the recyclable content, a high-plastic fraction from IT devices, in our case keyboards, were included in the studies. In total, 99 pieces of waste equipment underwent manual disassembly. Then the fractions produced were weighed and the results listed in a table.

The high content of plastics could be confirmed in the different types of device. Whereas the comparative group “keyboards” exhibits over 80 % plastics, in the “kettles” and “coffee machines” groups there are just under 70 % plastics. In the “toasters” and “irons” category, with around 50 % resp. 40 %, the highest iron metal contents can be found. The fraction of cables is the largest with 28 % in the hairdryers and 15 % in the irons. The low percentage of cables in the “kettles” category can be attributed to the nature of the examination. The bases with which the kettles are connected to the electricity grid could not be clearly assigned to the respective device in every case and were therefore not included in the evaluations. A special feature is shown by the “hairdryers” fraction. Installed in these appliances are motors to drive the fan which consist of iron and copper and make up around 20 % of the total mass.

Breakdown of the WEEE turned out to be difficult. On account of adhesive bonds and plug-in connections, a non-destructive opening of the devices was not possible. Prying open of the joints was only possible with great force and consequently increased risk of injury. On basis of the coarse separation, the allocation of the different recyclables to groups proved advantageous. To summarize, manual disassembly can nevertheless be rejected as a process for the breakdown of high plastics fractions in Collection Group 5 on account of the time requirement and injury risk.

Copper potential in device cables of small household appliances

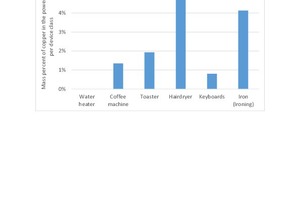

The findings described above show that different material groups are contained in the broken-down small electrical appliances. The cable fraction has the largest potential for the sale of the separated recyclable fractions. For one tonne of commercial cables with plugs, € 1 090 can be currently obtained. For the sale of pure copper, on the other hand, a price up to € 4 500 per ton (status 10/2020; source: Schrott24.de) and higher can be achieved, which makes further processing interesting.

To find out what mass percentage of copper is contained in each cable, the lengths, cross-sections and number of conductors were determined and recorded in writing for each device. Then the cable sheathing and the plugs were removed, and the masses of the different components determined (Fig. 2).

As the main task of small household appliances often involves the generation of heat, high power rates have to be transferred over a relatively long period of time. For this, the cable cross-sections are larger than cables for multimedia devices like the cables of the keyboard fraction included for comparison. Mainly, conductor cross-sections of 0.75 mm² were found. In the case of the keyboards, it was noticeable that the contained copper strands have a cross-section of 0.08 mm². Because of the small cross-section, these were difficult to separate from the sheathing. For this reason, the copper mass had to be calculated in this case.

If the use of plastics continues to increase in future, the device cables present a reliable basis for calculation of potential revenues from WEEE.

Determination of the composition of plastics in small electrical appliances

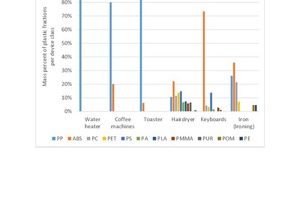

While the already liberated ferrous and non-ferrous fractions can be sold directly, further processing is required for the plastics. For identification of the types of plastic in the dismantled small household appliances, a sliding spark spectrometer is used. As a result, it was possible to detect black plastics and undertake a classification.

Problems are caused in this process, however, by bonded plastics. Especially in the “hairdryers”, “irons” and “keyboards” categories, a large number of plastics are used which have to be separated from each other in an additional separation step. It can be established that the most common plastics in our studies are polypropylene (PP), acrylonitrile butadiene styrene (ABS), polycarbonate (PC) and polystyrene (PS).

As manual sorting of WEEE plastics is no longer viable in practice, here mainly near-infrared technology (NIR) is used for sorting plastics. To obtain information on the possibilities of separation and identification of shredded WEEE, an exemplary sample was put together from the daily delivery of Collection Group 5 at Nordthüringer Werkstätten gGmbH and subjected to mechanical comminution. For this a single-shaft shredder from the company Weima was used. The small electrical appliances were shredded to a particle size < 30 mm and then sorted manually.

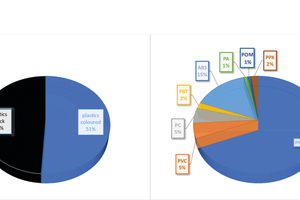

To identify the plastics downstream, a near-infrared workplace was used. As no black plastics can be detected by means of commercially available NIR technology, the manually separated plastic fraction had to be separated into visible plastics and black plastics. The sorted fractions obtained consisted of 49 % black and 51 % coloured plastics.

For determination of the types of plastic used in the production of the appliances, the fraction with the “visible plastics” was analysed at the NIR workplace. It was shown that PP with 69 % and ABS are the most common plastics contained in the appliances.

Sampling and analysis

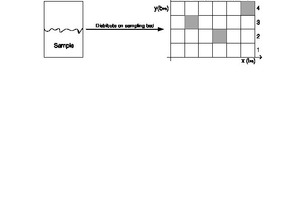

Problems in conducting sorting analyses of shredded WEEE include the lack of possibilities for the representative reduction of fractions to be sampled with over 10 l sample volume. To find a remedy here, on the basis of the already obtained findings in sampling at Nordhausen University of Applied Sciences, a new method was developed for sample reduction that is oriented to the two already published DIN standards 54385 und 54389 for representative sampling and LAGA PN98.

With the use of a so-called sampling bed, a sampling volume is fed onto a grid. Here there are 50 evenly distributed containers with a uniform volume of one litre. The sampling bed is divided into five rows of containers in the y axis and 10 rows in the x axis. The sampling material, which is free-flowing and has a particle size < 40 mm, is fed onto the “bed” and filled into the containers embedded into the surface. Then with the help of a random generator and a grid, a defined number of containers are removed which add up to a laboratory sample of ten litres. A further reduction to an analysis sample size of a few grams is now possible with an additional representative reduction step based on application of the already standardized pressing drill method DIN 54385. If no analysis sample is required, the 10-l laboratory sample can be manually sorted into the individual components.

As the sampling system is still under development, final results are not currently available. It can, however, be seen that representative sampling is possible. From the first tests, it can be concluded that the particle distribution in the respective containers is statistically similar. With a use of multiparticle mixes, it could be demonstrated that the distribution is representative. On the basis of the results, further tests are performed to understand the influence of the number of the fractions and their influence on the particle distribution. To compare the sampling bed method with removal from the ongoing process, a test sample was prepared according to LAGA DN98, DIN 19698-1 to 6 and DIN EN 15442. Exact conclusions can, however, only be drawn when other tests are performed. Here, the intention is that different materials, particle shapes and particle sizes are taken and sampled.

In addition, the plan is to design the sampling bed to be adjustable for larger sample volumes. With this, applications for the sampling process can be widened and a solution created for materials that are difficult to sample.

Processing concept for optioned WEEE primary treatment facilities

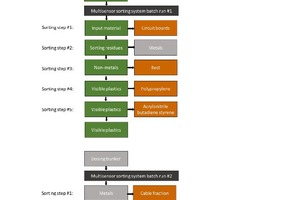

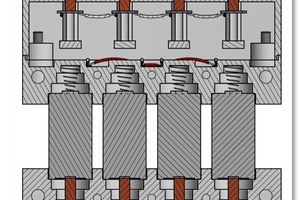

As part of the evaluation of the results and on the basis of market research conducted in the field of recycling technology, the use of a multi-sensor sorting system with near-infrared spectroscopy, inductive sensors and sensors for shape and colour detection as the main components of a processing plant at the primary treatment facility appears expedient. With the help of mounted compressed air nozzle bars, a large number of different materials can be separated and sold as a result. At the same time, the separation of plastics is enabled.

Even if such a plant does not appear profitable at first glance, all important processing and separation steps for modern processing of small electrical appliances can be effected. To achieve maximum sorting depth, the fractions must be fed to the plant in batches, one after another. For better adaption of the plant parameters to the waste-derived resources to be separated, recirculation of the material should be ensured.

The feed material is shredded with a suitable shredder adapted in terms of its throughput rate to the annual volume of the primary treatment facility to a particle size < 40 mm and transported on a belt conveyor to a bin for buffer storage. With interchangeable screen liners at the shredder, the particle sizes and liberation of the shredded material can be adapted. Upstream of the shredder, a removal of the pollutants is essential. For the batteries removed here, a possibility for discharge and transport was developed as part of the project, which is discussed in further detail below.

For processing, the shredded material is transported on a belt conveyor from the feed bin to a vibrofeeder. Thanks to the vibration, the particles of feed material are spaced out, separate from each other, and distributed over the entire width of the acceleration belt of the multi-sensor sorter. The fractions to be separated are oriented to the recyclables contained. Separation of circuit boards in Process Step 1 should only be performed if as the result of processing of small electrical appliances from the multimedia sector there is sufficient input of this subfraction. The target recyclables are separated by means of a compressed air nozzle bar mounted at the end of the acceleration belt. Here the material is selectively “shot out” over a separating vertex and separated in this way. The flowchart in Fig. 12 shows the sorting of a mixed small electrical appliance fraction of Collection Group 5.

With regard to the visible plastics, the primary aim is to separate the most common plastics. In our studies, these are PP and ABS. The other types of plastic can be separated directly in additional process steps or collected until a target mass worth processing is reached. With a concentration process, machine capacity utilization can be increased, and the necessary plant set-up times shortened.

Counting and sorting of spent batteries from the project partner “Nordthüringer Werkstätten“

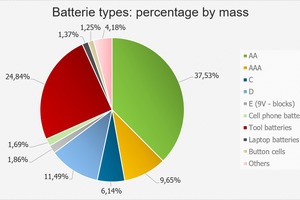

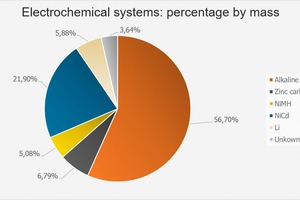

As part of the “InnoWert” project, for preparation of the further recycling of spent batteries, a discharging station for electrical energy storage from the post-consumer WEEE sector is being developed and tested. The focus is on evaluation of the use of residual energy potentially existing in the batteries as well as the safety aspect in the collection, treatment and transport of lithium ion batteries. As knowledge of the battery types in relevant quantities was necessary for the design of such a discharging station, in a first step, the quantity of spent batteries amassed over a defined period of time at the project partner Nordthüringer Werkstätten was counted. The batteries were first sorted manually by model and then by electrochemical system. The batteries were visually inspected to determine the percentage of defect batteries was determined, which based on defined criteria were classed as being not dischargeable in the discharging equipment, like damaged, deformed or severely corroded battery cells.

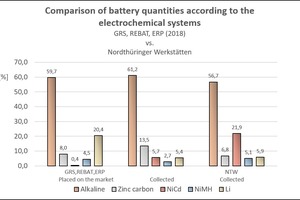

In total, 7 782 device batteries with a total mass of 214.7 kg were counted. The most frequent types were round cells of the type AA (37.53 %), D (11.49 %), AAA (9.65 %) and secondary batteries from power tools (24.84 %). These were mostly alkali-manganese cells (56.70 %), followed in terms of frequency by nickel-cadmium cells (21,90 %), which came almost exclusively from the power tools. The content of the lithium cells (5.88 %), which require additional attention for safety reasons, was relatively low and on a par with batteries of the other electrochemical systems.

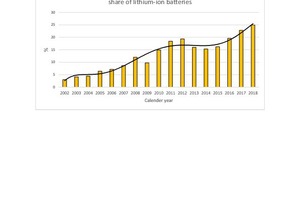

Comparison with the quantities of batteries placed on the market and collected quantities of batteries in the GRS, REBAT and ERP return systems shows similar percentages of the collected quantities of lithium batteries, but also shows that essentially higher percentages can be registered in the quantities of batteries placed on the market. Equally, a steady increase in the quantities of lithium batteries place on the market can be seen in recent years. While these still totalled around 3 % in the GRS return system in 2002, this value had increased to 25 % by 2018. The much lower quantities of collected lithium batteries can be attributed to the fact that the lifetime of many batteries has not been exhausted so that a considerable increase in the percentage of collected lithium batteries can be expected in the years to come.

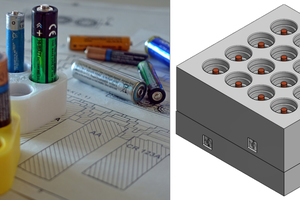

Discharging tests and determination of amounts of residual energy in spent batteries

For the further studies in respect of the design of the discharging station, on the basis of the counting results, the focus was placed on the round cells of the AA and AAA batteries. In view of the increased return of lithium cells already placed onto the market expected in the next few years, focus was widened to cover cells of the CR123 and 18650 batteries as these types can be integrated into the planned discharging module with limited additional design effort. As the discharging module is fabricated by means of 3D printing, later adaption to other battery types with round cell design can be easily realized.

To estimate the expected residual energy from the batteries, in the next step discharge tests were performed on a defined selection and number of batteries of the different types and systems. In respect of the possible future continuation and widening of the research work, the power tool batteries and the lithium cells from mobile telephones were included in these tests.

For the round cells of the AA and AAA types, voltage classes were defined, and, after measurement of the terminal voltage, all cells were allocated to one of these classes. From each of these voltage ranges and the different electrochemical systems, a defined number of cells was then discharged with the discharging electronic system to a defined limit and the energy emitted in this process determined. Depending on the mass percentage of the individual battery groups in the population of the respective type, the residual energy value was input as a percentage into the calculation of a mass-specific energy level.

Deviating from this procedure, all batteries of the power tools and the mobile telephones with a measured terminal voltage of at least 50 % of their nominal voltage were subject to a discharging test. Preliminary tests had shown here that below these levels, no practically relevant residual capacities were to be expected. The discharging of the lithium cells was possible only up to the respective limit of the discharging electronics integrated in the battery.

As a result, for the tested battery types, mass-specific levels of residual energy were determined (Table 1).

The highest content of potentially usable residual energy could be registered in the AA cells with 13.6 Wh/kg or.13.6 kWh/t. In second place came the AAA batteries with residual energy of 4.6 Wh/kg or 4.6 kWh/t, followed by the batteries from mobile telephones with 4.2 Wh/kg or 4.2 kWh/t respectively. Although for the high mass-specific content of the tool batteries, too, a higher level of residual energy was expected, this was the lowest of all tested types of battery with just 0.4 Wh/kg or 0.4 kWh/t.

Development and construction of a discharging station

The design of a prototype for the discharging of the defined battery type selection was based on the determined energy levels and characteristics of the battery types. Focus was on a modular construction that offers the prospect of transporting safety-relevant battery types in the discharge module, so that this can perform the function of short-circuit-proof transport packaging especially for high-energy lithium cells.

Basically, the designed discharging station consists of the discharging module for holding the batteries, a converter to convert battery residual voltage to a usable level for the downstream energy storage unit and the storage unit itself. For the planned tests, an electronic system was chosen that is capable of transforming residual voltage down to a lower limit of 0.3 V into a higher voltage, to charge an energy storage unit based on a lithium ion battery.

The discharging module for holding the four intended battery types was designed based on the battery geometries with PC software and fabricated by means of 3D printing from the bioplastic polylactide. Planned in the further course of the project is the completion of the modular units and the testing of the integrated unit in respect of suitability for its intended purpose. On account of the good scalability of the prototype, an extension of the range of application is feasible based on adaption to the manufacturer-specific battery types.

Use of the discharge register as a transport solution safe from hazardous substances

This adaptability is at the same time also the essential reason to use the designed discharge register as a possibility for the safe transport of lithium batteries. With its simple design and uncomplicated reproducibility by means of 3D printing or injection moulding, which enable very easy adaption to a wide range of battery sizes and easy use, it presents an alternative packaging and transport unit. The batteries are placed in defined positions to each other, which is not guaranteed with a loose filling. Masking of the battery poles is not necessary as these are embedded in a practically non-electrically-conductive plastic and are safe from short circuiting. For the case that a further discharge by means of the discharging station is not planned, the discharge register can be used a straight transport solution without additionally installed electrical or electronic components.

To estimate the potential necessity and requirement for a discharging station beyond that of the project partner Nordthüringer Werkstätten, a survey was conducted to determine the current situation regarding the collection and treatment of the spent batteries at primary treatment facilities and recycling depots. For this purpose, a questionnaire was sent to 21 companies with a total of 99 sites.

Core content were questions concerning current practices in collection and treatment of spent batteries, especially of lithium batteries, safety-relevant incidents such as fires caused by post-consumer batteries, the evaluation of the technical practices of battery treatment, individual wishes for change and improvement compared to previous practice and – especially in respect of possible negative previous experience in battery collection – the use of a discharging station for batteries from technical and economic perspectives.

In the feedback from nine companies with 39 sites, three incidents with lithium batteries were documented in which minor fire events resulted. Four of the companies take a positive view of the use of a discharging station from a technical perspective, at the same time, however, they rate the current handling practices in battery collection as predominantly adequate. In respect of additional costs for the acquisition and operation of a discharging station, seven of the companies see economic factors as an obstacle to their use.

A second survey among freight forwarders and transport companies is planned to widen the focus in order to cover the safe transport of lithium batteries and is scheduled for completion in the further course of project work in the last quarter of 2020.