Weighing at the discharge point

In the recycling sector, there are often materials that are very valuable, but do not occur in quantities that can be weighed with a built-in belt scale. In addition, the weighing should also be very accurate.

The new conveyor discharge weigher from MTS MessTechnik Sauerland GmbH offers a supplement to classic built-in belt scales and solid flow meters when these cannot be used due to the low feed rate, the bulk material properties or the installation situation.

The conveyor discharge weigher type CDW is ideally suited for the recording of small to medium feed rates from 200 up to 5000 kg/h. The weighing is performed statically – therefore these scales achieve very accurate measurement results.

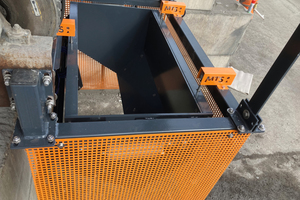

The scale consists of a weighing hopper with a pneumatically downward opening discharge flap and a robust subframe. The subframe is permanently installed on the discharge to the conveyor structure, while the actual weighing hopper is integrated into the frame with the help of precise load cells.

The material to be conveyed is then transported via the conveyor system (e.g. conveyor belt) to the discharge point, where it falls into the closed weighing hopper – until a defined fill level or weight value is reached. The infeed is then briefly stopped in order to weigh the hopper accurately. The discharge flap then opens and the hopper is emptied. The flap closes again, the hopper is tared and the infeed and the next weighing cycle are started.

The ModWeigh Batch weighing electronics control the filling and emptying processes and evaluate the load cell signals. On the one hand, the electronics record the weight value of the weighing hopper and accumulate the individual batch values in the totalizer; at the same time, the ModWeigh also generates the feed rate in kg/h or t/h from the weight values of the individual batches and the time unit determined for a weighing operation. The flap is controlled self-sufficient via the weighing electronics. The flap position is monitored by a proximity switch.

The conveyor discharge weigher type CDW can also be retrofitted into existing systems with little effort.

The scale is supplied in painted steel as standard, with stainless steel available as an option. All heavily stressed parts of the hopper and the discharge flap are made of Hardox. For safety reasons, the scale is also equipped with a protective grille.