IMPAKTOR 250 evo takes family-owned recycling company to a next level

Myles and Aimee Tichband have always been involved in the recycling industry. In 2015, they decided to rebrand and started Copia Metals. To complete their goal, they needed a larger and more suitable site, which they found in Charlton in south east London.

Aimee Tichband, Managing Director of Copia Metals & Waste limited, talks about the day-to-day challenges of her business and the deal she was able to strike with Arjes UK distributor, Doyle Machinery: “With both Copia Waste and Copia Metals growing exponentially, the biggest challenge we face is recycling and managing the material we receive. Specifically at our waste transfer station, general construction waste is what we deal with, on a day to basis, from sites in and around London and trying to hit our recycling targets in a quick, effective, environmentally friendly manner is one of the core values that set us apart from other companies, that’s why we believe it is an aspect which needs to be continuously monitored in order to improve it.”

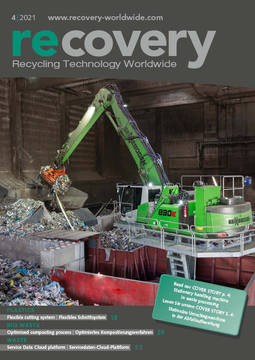

This challenge led to the latest purchase – the ARJES IMPAKTOR 250 evo – custom-made for Copia green! Doyle Machinery is very well known within the waste and metal industry, so they were the first port of call when looking to purchase a shredder. Patrick King from Doyle machinery gave first-class service, great advice and arranged everything, right down to the customization of the machine. Since the moment the company received the shredder, they have been able to speed up the recycling process by collecting the various waste streams, processing them directly and sorting them into different recyclable categories, as well as saving well needed space by reducing the volume of the material, therefore, more waste can be processed on site.

Copia Metals & Waste Ltd. wanted a machine that is sturdy enough to meet the high standards for waste and metal processing and that can carry out the process quickly and effectively. The faster they process the material at both sites, the less impact on the environment, which is the main reason why the company decided to choose ARJES. The built-in water spraying system allows to work within close proximity to the neighbors without causing significant dust pollution.

The company purchased both the metal and waste shredding tool shafts with cassettes, which are easy and trouble free to change making the IMPAKTOR 250 evo perfectly versatile for both sides of their business.

“We can’t wait to see what Copia Metals & Waste has in store for the rest of 2021. We are committed to stamping out waste to landfill and recycling 100 % of all metal and waste streams that we deal with,” Aimee Tichband said. “We’ve recently looked into waste for fuel plants and are hoping we can make further progress in our recycling mission.” The company continues to re-evaluate the operational methods and adapts the machinery to meet the challenges of the industry, while working hard to do their part for the environment. The ARJES machine has dramatically changed the way of recycling and has made hitting the recycling goals simple & easy: 100 %.