TES announces expansive new battery recycling services

29.11.2019

© TES

© TES

TES announced the opening of two new battery recycling facilities – TES B in Singapore and Recupyl in Grenoble/France. The approximately $ 25 million investment positions TES as a leader in the lithium battery recycling market and the growing second life battery space.

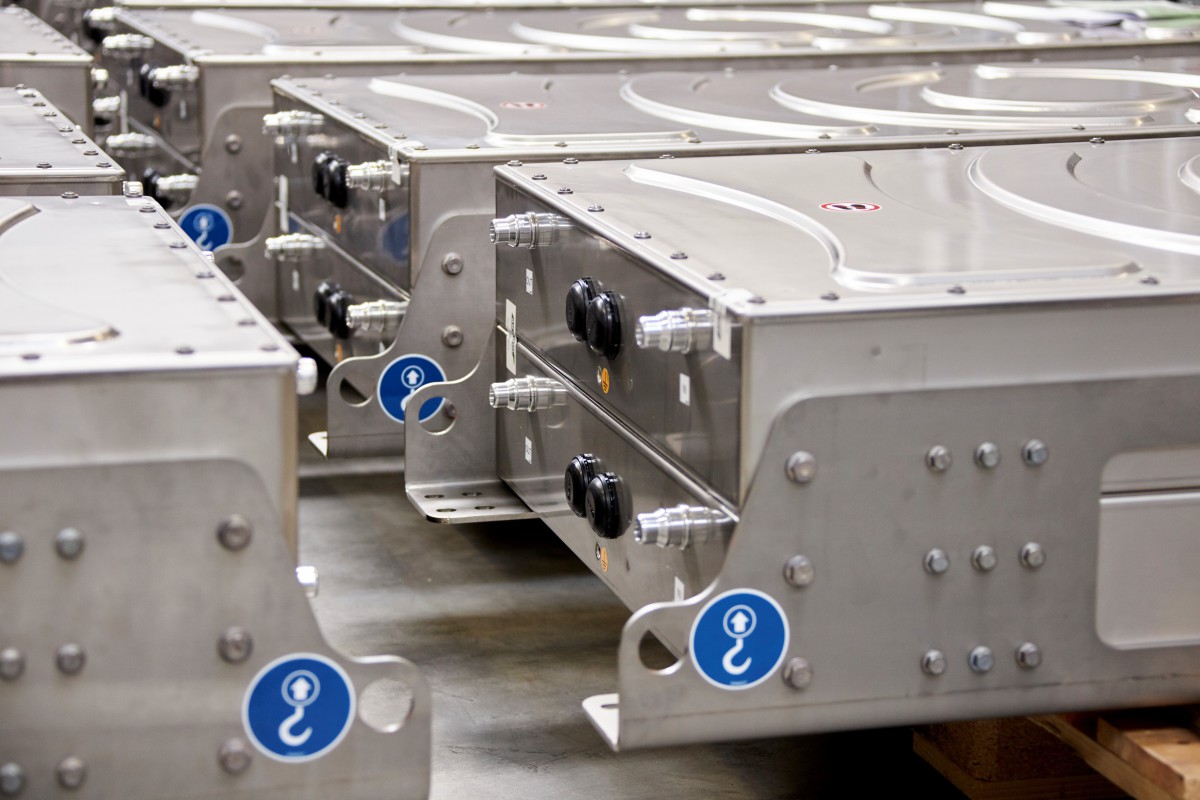

Each facility employs an innovative recycling process utilising proprietary in-house technology and equipment. Auto punching machines and shredders break end-of-life batteries down into fine substances. Magnetic separators recover the copper and aluminum, and a chemical treatment process is used to recover commodity-grade cobalt and lithium. This process is environmentally friendly, as it does not release secondary contaminants like heavy metals or volatile organic compounds into the atmosphere.

This unique process yields the highest commodity-grade recovery rates in the industry. TES’s process also creates a complete closed-loop for lithium-ion batteries, eliminating the need to continuously source raw materials and deal with unreliable global suppliers. This means all recovered materials will ultimately be reused in the forward manufacturing supply chain and contribute to the circular economy.

Additionally, TES announced that they are working with strategic partners to develop the release of ESS (Energy Storage System), scalable turnkey solutions that use retired electric vehicle batteries for various commercial and residential energy needs in the secondary market. ESS uses a network of optimally connected second life battery cells to store electricity and is a viable power alternative for green energy plants, remote mining power, and Base Transmit Stations, among other applications.

“Investing in technology that keeps TES at the forefront of the sustainability movement is in our DNA,” said Gary Steele, TES’s Chief Executive Officer. “Looking ahead, the battery space is potentially facing raw material commodity shortages stemming from the exponential proliferation of Internet of Things devices, electric vehicles, and mobility devices. These real world challenges need real world solutions. Working in close partnership with the EDB (Singapore Economic Development Board) and the NEA (National Environment Agency) has enabled TES to develop an innovative battery recycling solution that further cements Singapore as being at the centre of the future circular economy.”

Already an industry leader in IT lifecycle services that understands environmental impact and global compliance, TES’s launch of TES B, Recupyl and ESS solidifies the company’s commitment to the circular economy, ensuring that batteries and their commodities are recovered and reused to address the evergrowing global demand for lithium batteries.

“As the first facility here to recover precious metals from batteries using a new hydrometallurgy process, TES B allows Singapore to offer closed loop battery recycling services, thus serving domestic needs and enhancing the regional value chain for e-waste management,” said Damian Chan, Assistant Managing Director, EDB. “In addition, as electric vehicle adoption and solar deployment scale up in Singapore, TES B and TES’s efforts in second-life ESS will contribute to our battery recycling and energy management ecosystem.”

“TES’ innovative battery recycling solutions will contribute to closing the resource loop for lithium batteries and support Singapore’s upcoming Extended Producer Responsibility system to manage ewaste. TES’ efforts are also aligned with the vision outlined in Singapore’s Zero Waste Masterplan to build a sustainable, resource-efficient and climate resilient nation,” said Ananda Ram Bhaskar, Deputy Chief Executive Officer (Environmental Protection) of the National Environment Agency (NEA).